Automatic LED opening and closing screen

specifications

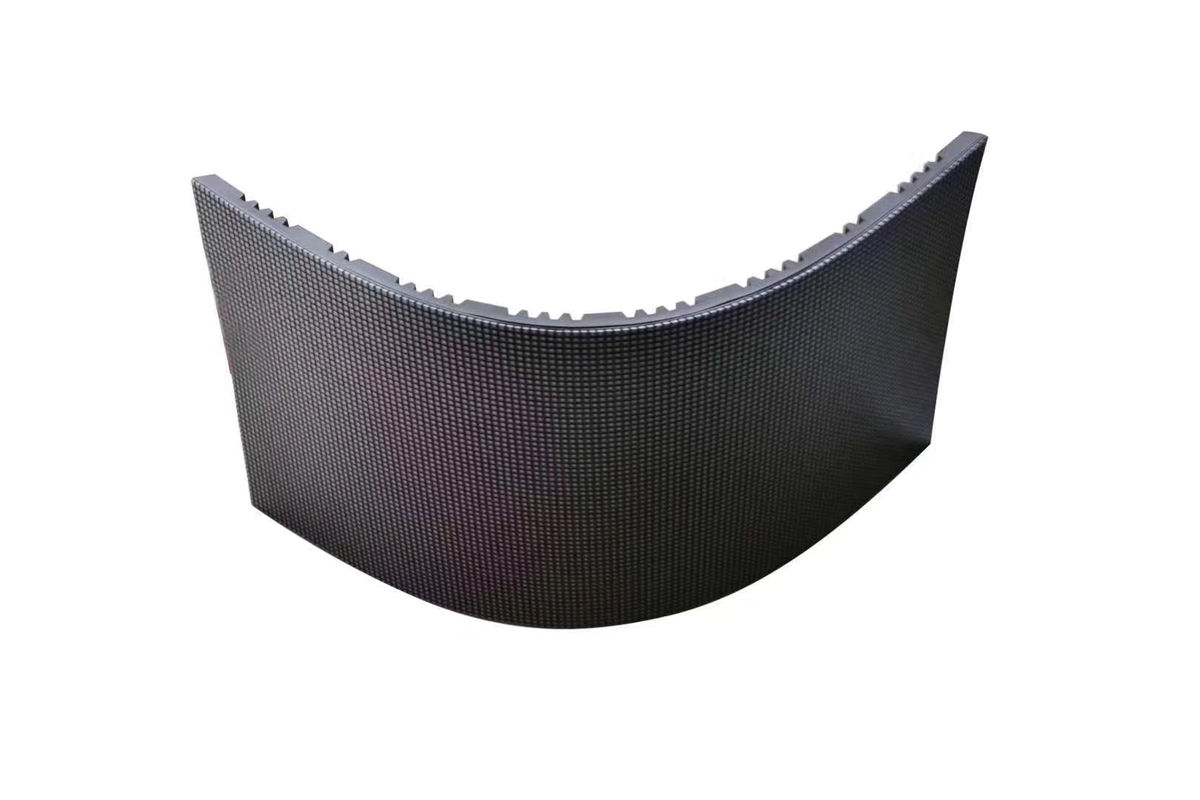

Automatic LED opening and closing screens can be installed indoors and outdoors. Conventional indoor and outdoor models can be customized. The opening and closing screens can also be made into a 360 ° curved opening and closing screen. The module can be selected according to actual needs and curvature, and there are two options: soft film group and curved box

application

Currently, the first tier cities in Beijing, Shanghai, Guangzhou, and Shenzhen are widely used, mainly in conference rooms, partitions, high-end buildings, buildings, hotels, stages, and wedding celebrations

Automatic LED opening and closing screens can also be used in stage rental series, creating unique and unique spaces in different locations.

This product is an automatic LED opening and closing screen produced from LED chips (secondary light-emitting tubes), not a touch screen or LCD screen

Latest quotation

The production process requirements for automatic LED opening and closing screens are relatively high, and the cost has increased compared to conventional models. The prices displayed in the price section of this page are for reference only. The latest real-time prices fluctuate with the market, and the company will update the automatic LED opening and closing screen quotation once a month in a timely manner

Parameter Description

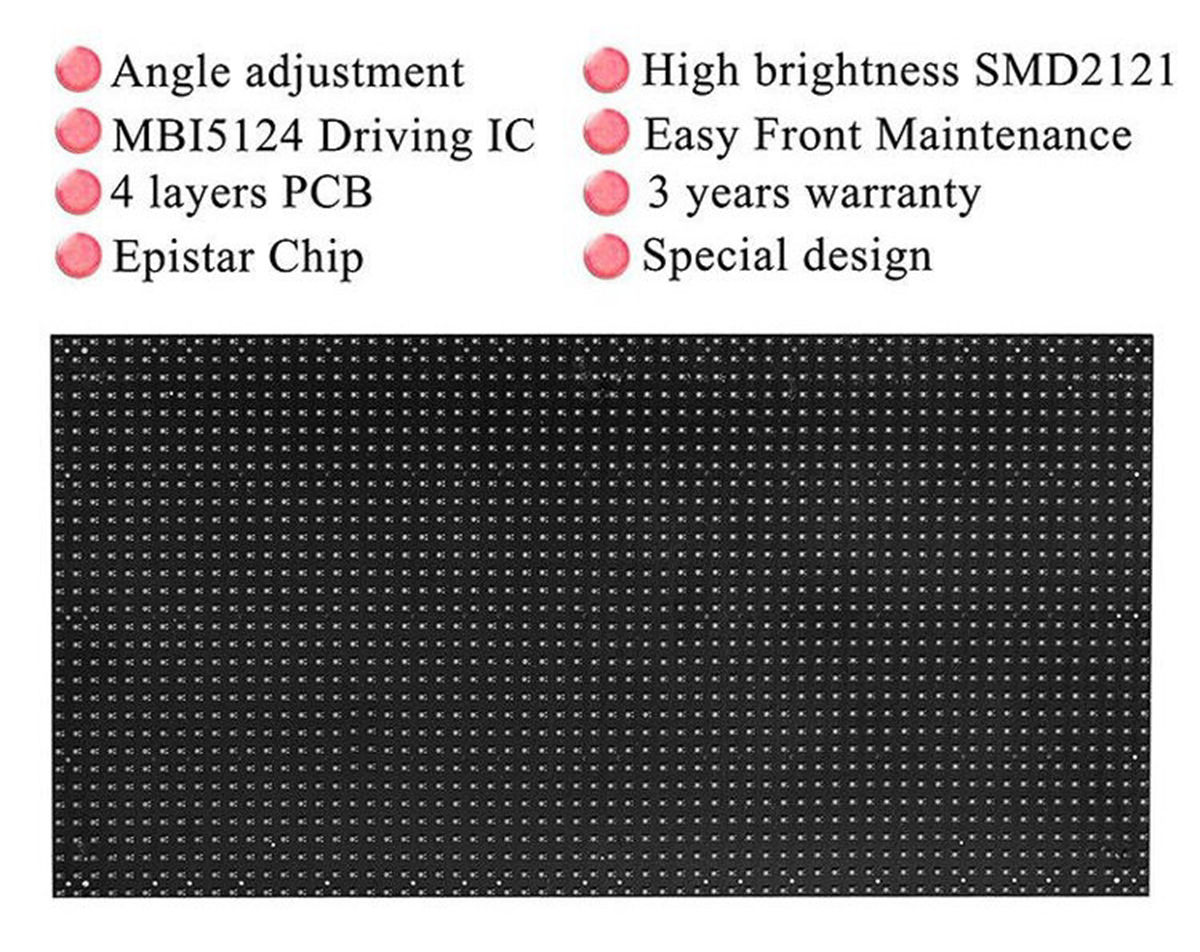

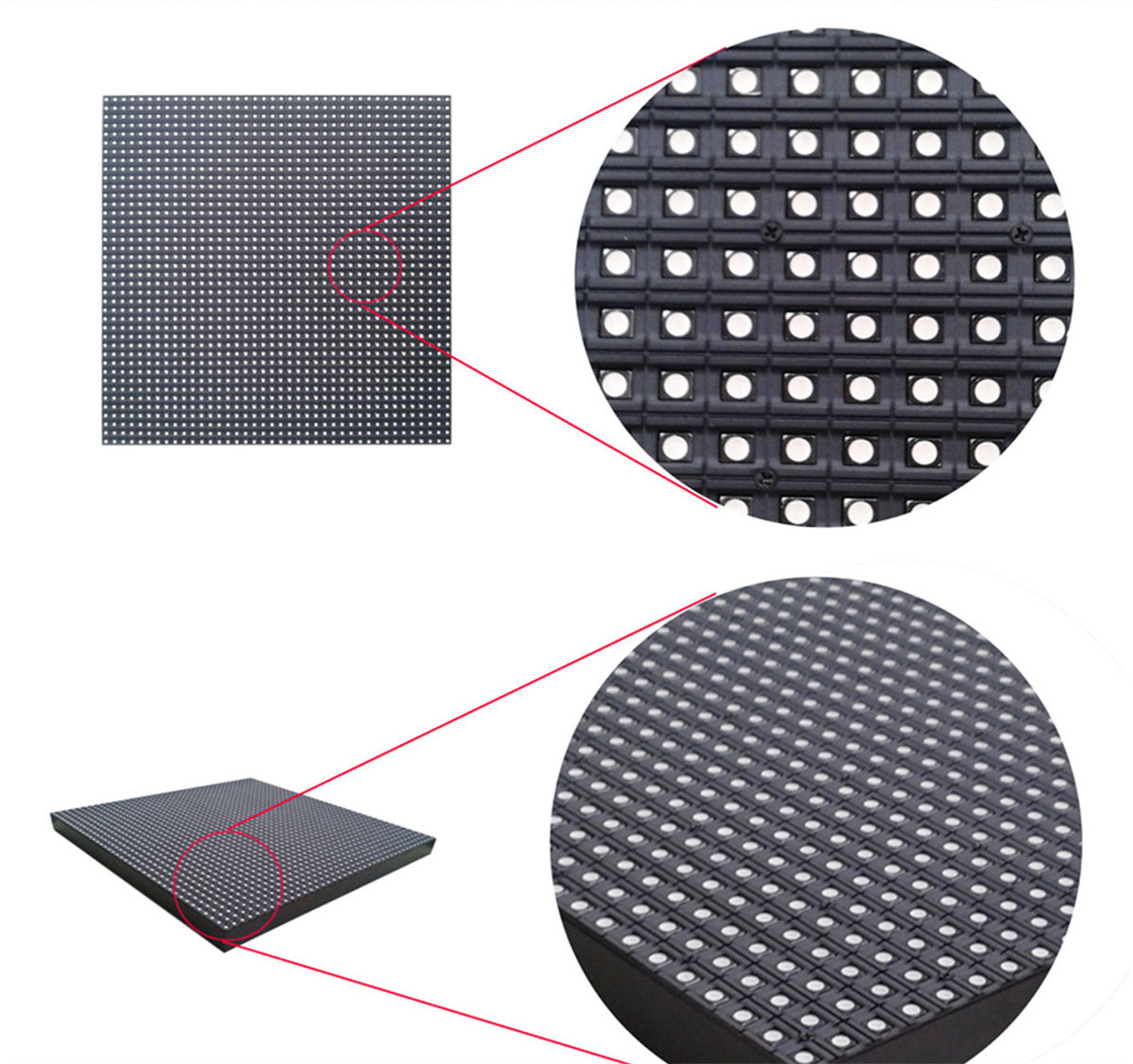

The parameters of the automatic LED opening and closing screen are mostly the same as those of the conventional LED display screen, with the difference being that the module, box, display parameters, technical parameters remain consistent, and the final display effect is also consistent.

performance

The automatic LED switching screens currently produced are all full-color display screens, capable of displaying 16.77 million full colors, with RGB single core grayscale levels of 256, ensuring uniform color and high contrast of the display screen, clearer and more realistic display content, and stronger visual impact.

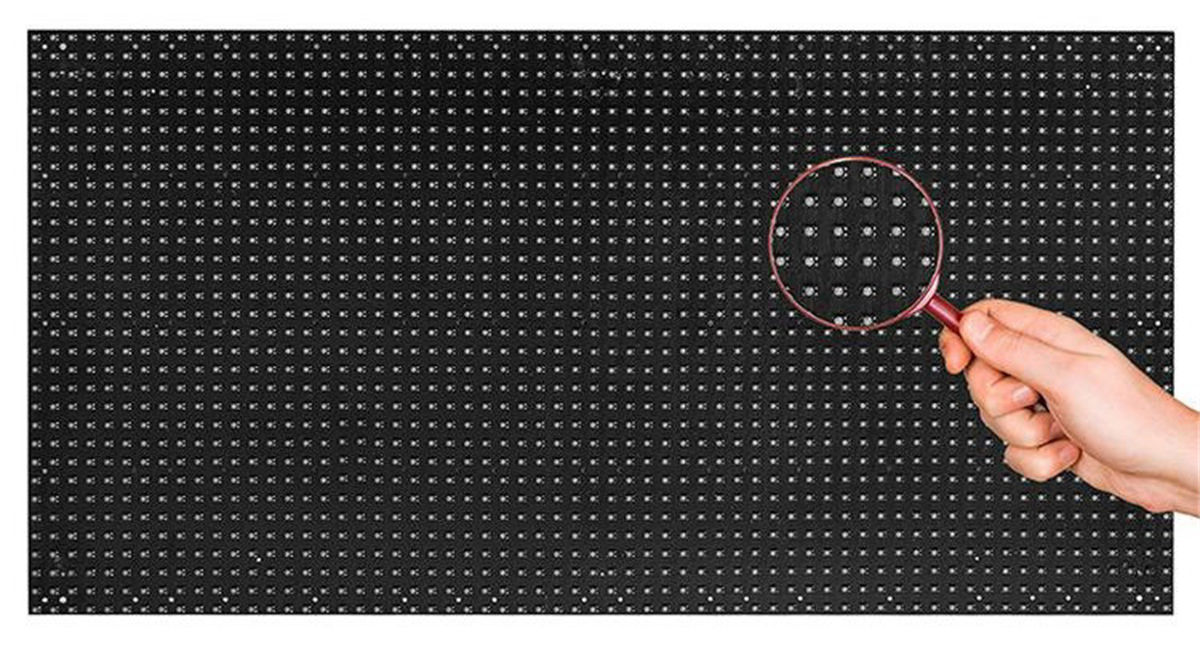

Using copper wire, alloy wire, and gold wire packaging, the signal receiving distance can reach 120 meters. The power supply is more stable during use, effectively delaying the oxidation time of the chip, greatly extending its service life, and the dead light rate has reached one in 500000.

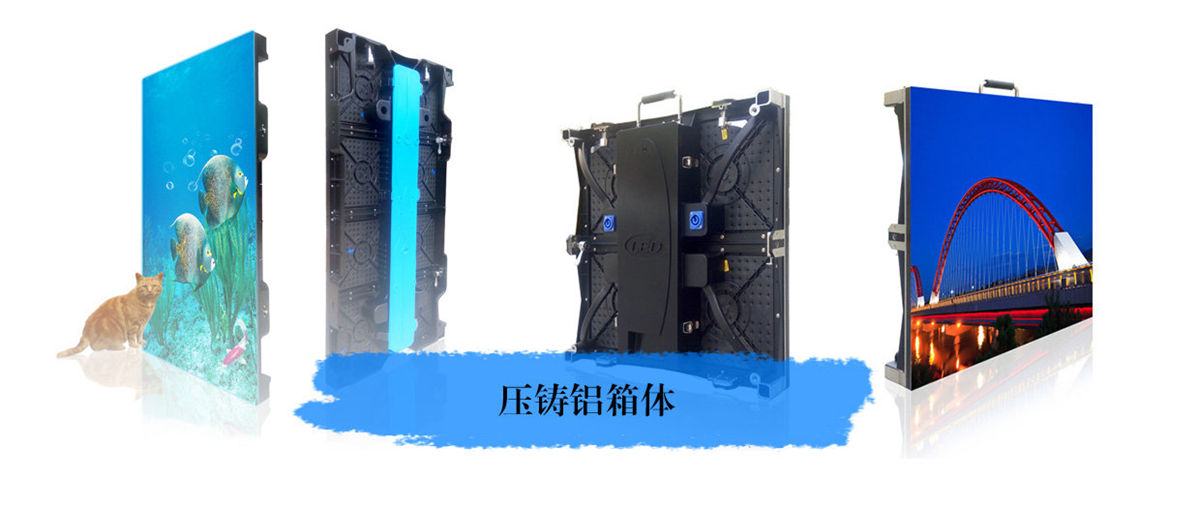

The automatic LED opening and closing screen box adopts high-temperature spraying technology, effectively preventing rust, and the flatness of the box is controlled at 0.1mm before and after installation. The die-casting aluminum box is also processed by CNC precision scientific digital processing, with a stronger overall sense of detail hierarchy and an error of less than 0.1mm, truly seamless splicing.

The automatic LED opening and closing screen not only uses high-end chips, but also comes with high-end control cards and high-quality power supplies. The combination of high-quality and strong components, coupled with strict quality control, ensures the high quality of the automatic LED opening and closing screen.

Outdoor automatic LED opening and closing screens can be waterproof and corrosion-resistant, and also have flame retardant and three-level lightning protection technology. They can be used in outdoor environments for a long time without worry.

Advantages of automatic LED screen opening and closing:

The quality of the automatic LED opening and closing screen produced by the manufacturer is a mid to high end product. In 2019, the dead light rate was only 500000/1, and it can be used with confidence within the 3-year warranty period.

Patent mask design, dust-proof and waterproof, with a protection level of IP65

Using unified pure copper wire to ensure stable signal and power supply, safe and reliable use

Ultra wide viewing angle design, with a maximum viewing angle of 145 °, expanding the audience range

Strictly control the procurement of raw materials, use unique anti deformation module kits to ensure that the screen body is flat and not deformed

Low power consumption, low heat, energy-saving and environmentally friendly, outdoor LED display screens only require a minimum power consumption of 280 watts

Standard waterproof box made of high-quality steel materials with precision processing, and the joint between modules is strictly controlled within 0.1mm

Uniform color, high contrast, beautiful and natural image, with no granular or mosaic phenomenon in the display effect, and good color uniformity performance

Ultra high brightness, up to 7000cd/㎡, paired with low attenuation, high reliability, and high weather resistance to perfectly display screen content and attract attention

The latest support for pre maintenance mode allows for disassembly and maintenance in front of the module, with maintenance speed more than 5 times faster than traditional LED displays, greatly reducing maintenance time